|

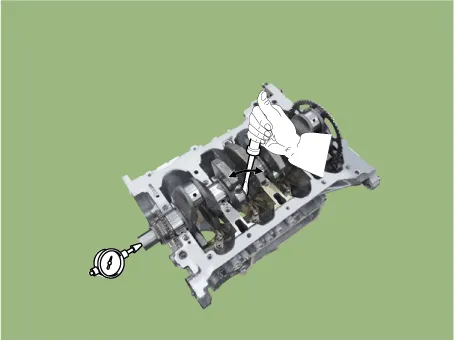

If the plasticgauge shows that the clearance is still incorrect,

try the next larger or smaller bearing (the color listed above

or below that one), and check clearance again.

|

• |

If the proper clearance cannot be obtained by

using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

|

|

• |

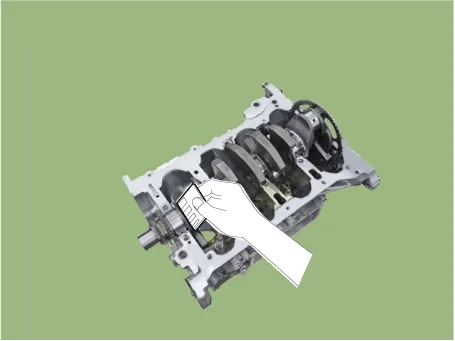

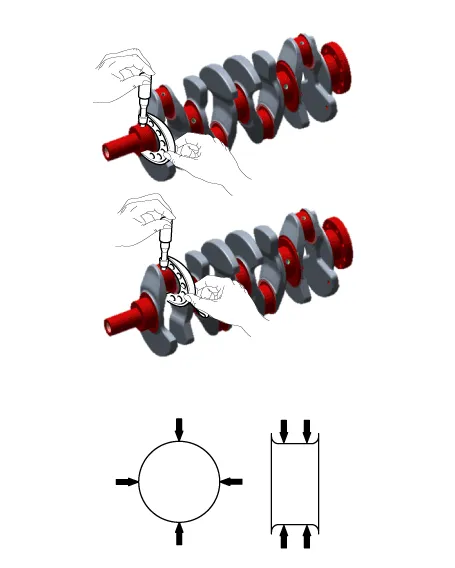

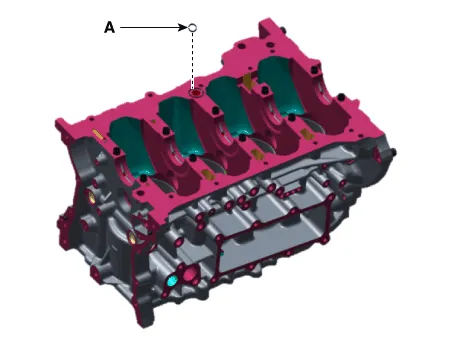

If the marks are indecipherable because of an

accumulation of dirt and dust, do not scrub

them with a wire brush or scraper. Clean them

only with solvent or detergent.

|

|

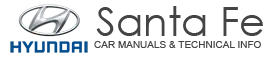

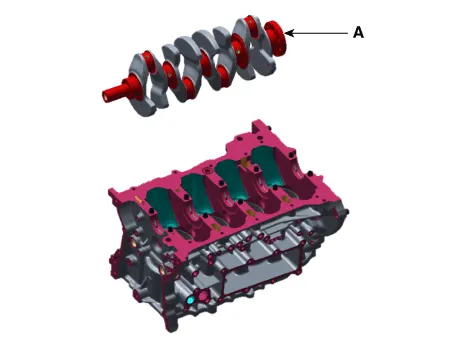

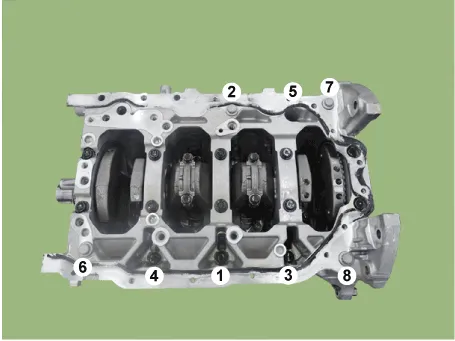

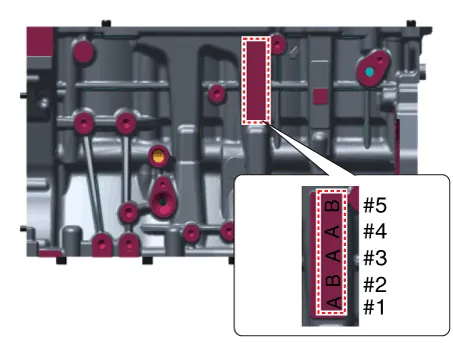

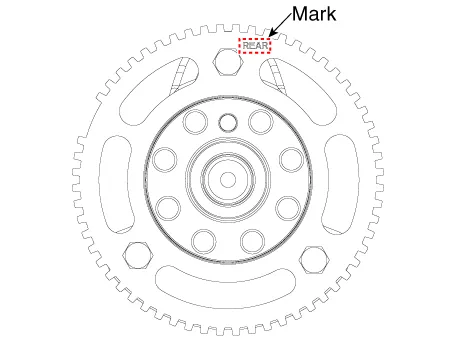

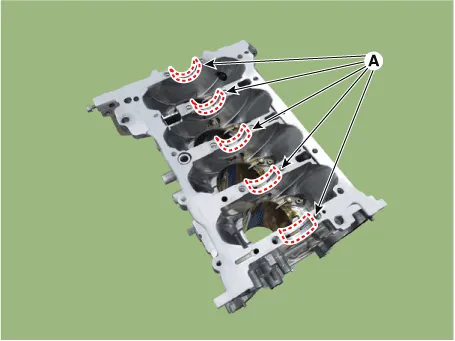

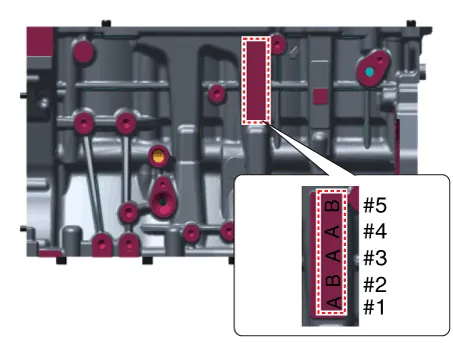

Cylinder Block Crankshaft Journal Bore Mark Location

Letters have been stamped on the side surface of the block as

a mark for the size of each of the 5 main journal bores.

Use them, and the numbers or letters stamped on the crank (marks

for main journal size), to choose the correct bearings.

Class

|

Mark

|

Cylinder block crankshaft journal bore inner diameter

|

a

|

A

|

57.000 - 57.006 mm

(2.2441 - 2.2443 in.)

|

b

|

B

|

57.006 - 57.012 mm

(2.2443 - 2.2446 in.)

|

c

|

C

|

57.012 - 57.018 mm

(2.2446 - 2.2448 in.)

|

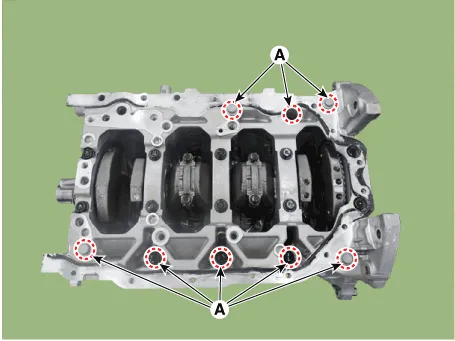

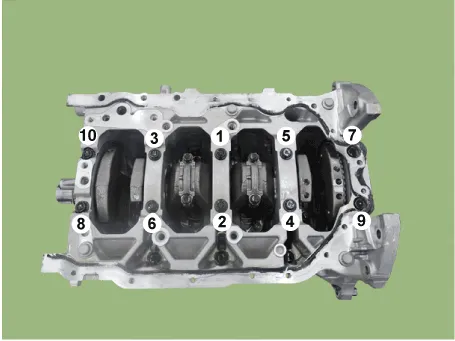

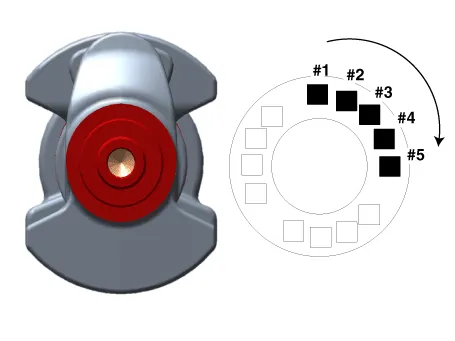

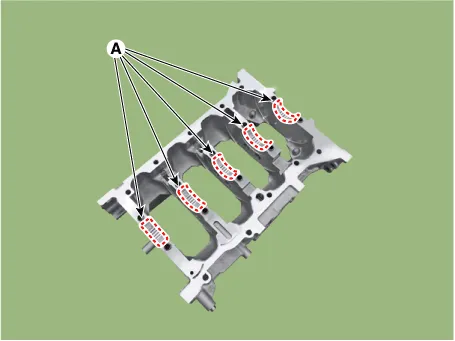

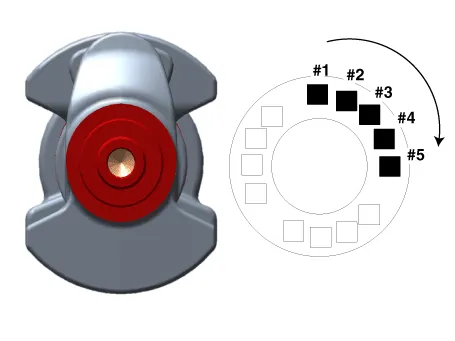

Crankshaft Main Journal Mark Location

Discrimination Of Crankshaft Main Journal

Class

|

Mark

|

Crankshaft main journal outer diameter

|

A

|

1

|

51.954 - 51.960 mm

(2.0454 - 2.0457 in.)

|

B

|

2

|

51.948 - 51.954 mm

(2.0452 - 2.0454 in.)

|

C

|

3

|

51.942 - 51.948 mm

(2.0450 - 2.0452 in.)

|

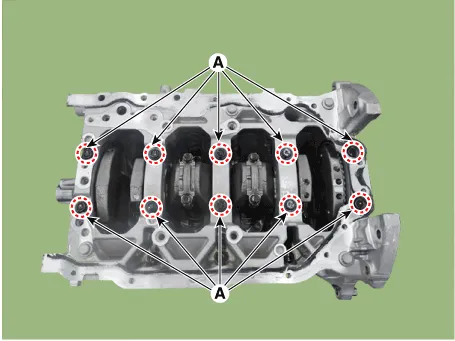

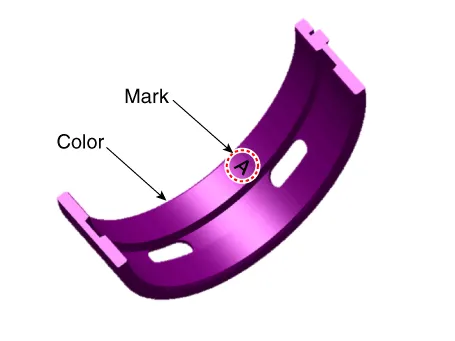

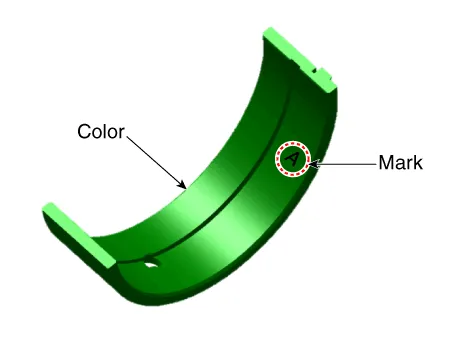

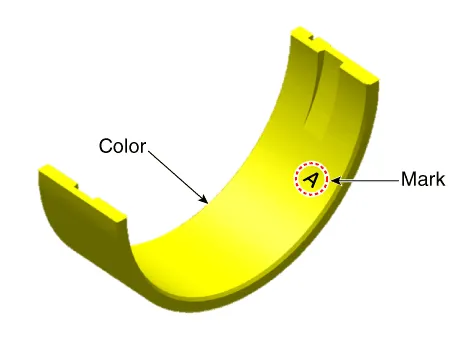

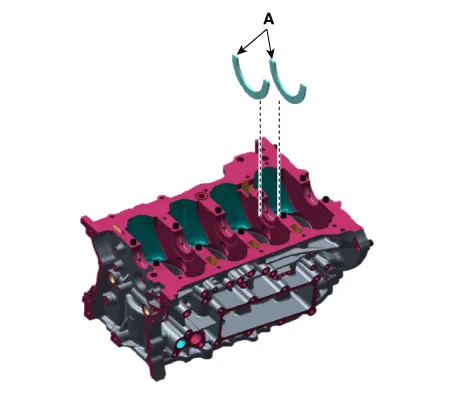

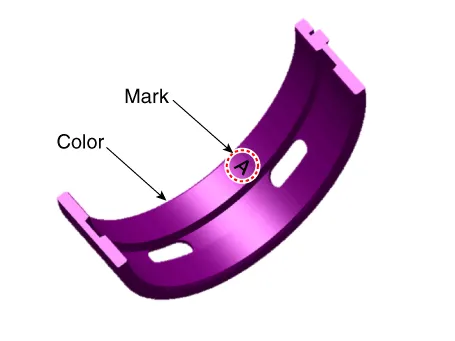

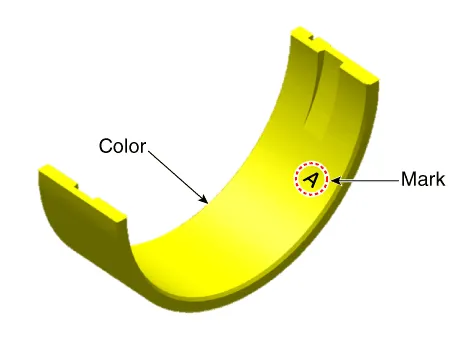

Crankshaft Bearing Identification Mark Location

[No. 2, No 3, No. 4 Journal Upper Bearing]

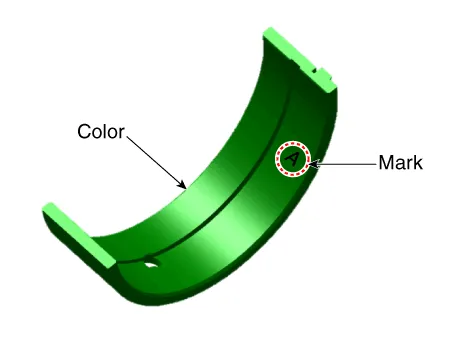

[No. 1, No 5 Journal Upper Bearing]

[Lower Bearing]

Discrimination Of Crankshaft Bearing

Class

|

Color

|

Bearing thickness

|

A

|

LIGHT Blue

|

2.518 - 2.521mm

(0.0991 - 0.0993in.)

|

B

|

Black

|

2.515 - 2.518mm

(0.0990 - 0.0991in.)

|

C

|

WHITE

|

2.512 - 2.515mm

(0.0989 - 0.0990in.)

|

D

|

LIGT GREEN

|

2.509 - 2.512mm

(0.0988 - 0.0989in.)

|

E

|

PINK

|

2.506 - 2.509 mm

(0.0987 - 0.0988 in.)

|

F

|

YELLOW

|

2.503 - 2.506 mm

(0.0985 - 0.0987 in.)

|

|