Hyundai Santa Fe (TM): Cylinder Block / Cylinder Block. Repair procedures

| Disassembly |

|

|

|

| 1. |

Remove the crankshaft.

(Refer to Cylinder Block - "Crankshaft")

|

| 2. |

Remove the knock sensor.

(Refer to Engine Control / Fuel System - "Knock Sensor (KS)")

|

| 3. |

Remove the crankshaft position sensor (CKPS).

(Refer to Engine Control / Fuel System - "Crankshaft Position Sensor

(CKPS)")

|

| 4. |

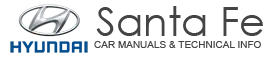

Remove the piston cooling oil jets (A).

|

| Inspection |

| 1. |

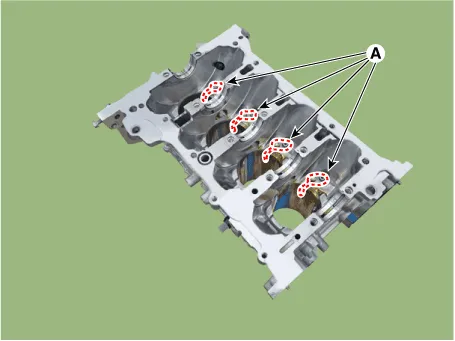

Using a gasket scraper, remove all the gasket material from the top

surface of the cylinder block.

|

| 2. |

Using a soft brush and solvent, thoroughly clean the cylinder block.

|

| 3. |

Inspect the top surface of cylinder block for flatness.

Using a precision straight edge and feeler gauge, measure the surface

contacting the cylinder head gasket for warpage.

|

| 4. |

Visually check for scratches on the inside surface of the cylinder bore

and replace the cylinder block if any noticeable scratch is detected.

If deep scratchs are present, replace the cylinder block.

|

| 5. |

Using the cylinder bore gauge, measure the cylinder bore’s inner diameter

to the axial and axial perpendicular directions.

|

| Reassembly |

|

| 1. |

Install the piston cooling oil jets (A).

|

| 2. |

Install the crankshaft.

(Refer to Cylinder Block - "Crankshaft")

|

| 3. |

Check the crankshaft end play.

(Refer to Cylinder Block - "Crankshaft")

|

| 4. |

Disconnect the lower crankcase and check crankshaft bearing oil clearance.

(Refer to Cylinder Block - "Crankshaft")

|

| 5. |

Install the piston and connecting rod assembly.

(Refer to Cylinder Block - "Piston and Connecting Rod")

|

| 6. |

Check the connecting rod bearing cap oil clearance.

(Refer to Cylinder Block - "Piston and Connecting Rod")

|

| 7. |

Check the connecting rod end play.

(Refer to Cylinder Block - "Piston and Connecting Rod")

|

| 8. |

Assemble the other parts in the reverse order of disassembly.

|

Disassembly • Be careful not to damage the parts located under the vehicle (floor under cover, fuel filter, fuel tank and canister) when raising the vehicle using the lift.

Coolant. Repair procedures Refilling And Bleeding • Never remove the reservoir tank cap when the engine is hot.

Other information:

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Smart Key. Repair procedures

Smart Key Smart Key Code Saving 1. Connect the DLC cable of diagnostic tool to the data link connector (16 pins) in driver side crash pad lower panel, turn the power on diagnostic tool. 2.

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Driver Parking Assistance System

Desctiprion and operation Description ADAS_PRK is a unit that controls the functions required for ADAS parking. If the ADAS_PRK is applied, the parking distance warning function is also controlled by the ADAS_PRK. System Function Parking Collision-Avoidance Assist (PCA) PCA is a parking safety system

Categories

- Manuals Home

- Hyundai Santa Fe Owners Manual

- Hyundai Santa Fe Service Manual

- Engine Control/Fuel System

- Instrument cluster

- Engine Electrical System

- New on site

- Most important about car