Hyundai Santa Fe (TM): Engine Mechanical System / Repair procedures

| Compression Pressure Inspection |

|

| 1. |

Warm up and stop engine.

Allow the engine to warm up to normal operating temperature.

|

| 2. |

Disconnect the injector extension connector (A).

|

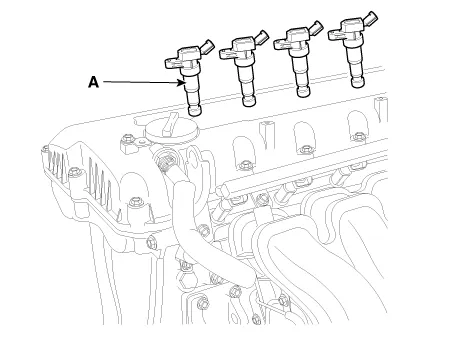

| 3. |

Remove ignition coils (A).

|

| 4. |

Remove spark plugs.

Using a 16mm plug wrench, remove the 4 spark plugs.

|

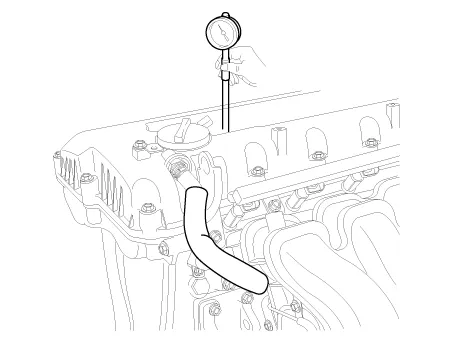

| 5. |

Check cylinder compression pressure.

|

| 6. |

Reinstall spark plugs.

|

| 7. |

Install ignition coils.

|

| 8. |

Connect the injector extension connector and ignition coil connectors.

|

| 9. |

Some DTC's may exist after the inspection test and may need to be manually

cleared with diagnostic tool.

|

Special Service Tools Tool (Number and name) Illustration Use Crankshaft front oil seal installer (09214 - L1100) (09231-H1100) Installation of the front oil seal.

Troubleshooting Symption Suspect area Remedy Engine misfire with abnormal internal lower engine noises.

Other information:

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Ambient Temperature Sensor. Description and operation

Description The ambient temperature sensor is located at the front of the condenser and detects ambient air temperature. It is a negative type thermistor; resistance will increase with lower temperature, and decrease with higher temperature.

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Rear Heater

Rear Heater Unit. Components and components location Component Location 1. Rear Heater & A/C Unit Components 1. Rear heater & blower unit assembly 2. Blower motor assembly 3.

Categories

- Manuals Home

- Hyundai Santa Fe Owners Manual

- Hyundai Santa Fe Service Manual

- Front Radar Unit. Repair procedures

- Battery. Specifications

- Troubleshooting

- New on site

- Most important about car