Hyundai Santa Fe (TM): Automatic Transaxle System (SBC) / Automatic Transaxle System

Automatic Transaxle. Repair procedures

| Removal |

|

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable.

|

| 2. |

Remove the air cleaner assembly and air duct.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 3. |

Remove the battery and battery tray.

(Refer to Engine Electrical System - "Battery")

|

| 4. |

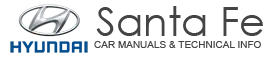

Loosen the bolts (B) and nut (A) and then separate the shift cable and

cable bracket (C) at the same time.

|

| 5. |

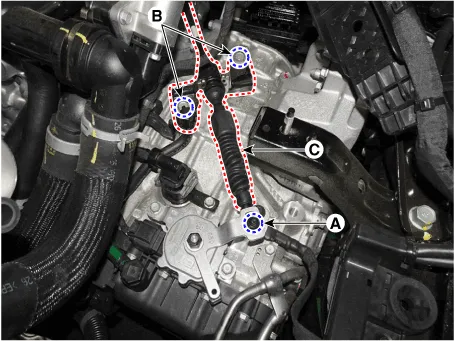

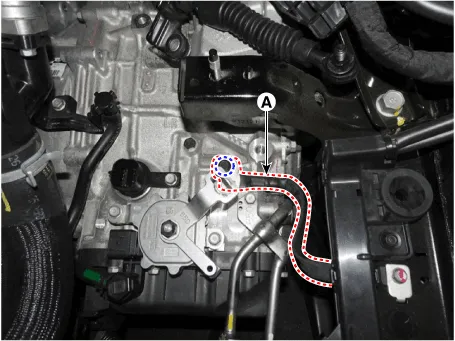

Dissconnect the main connector (A) and the position switch connector

(B).

|

| 6. |

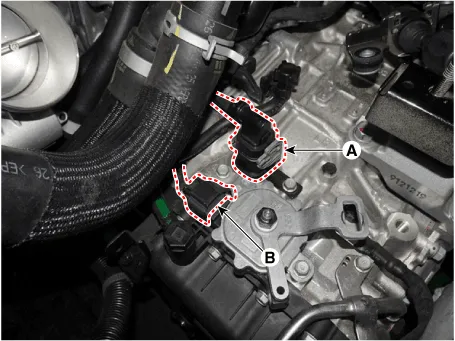

Separate the wiring clips (A).

|

| 7. |

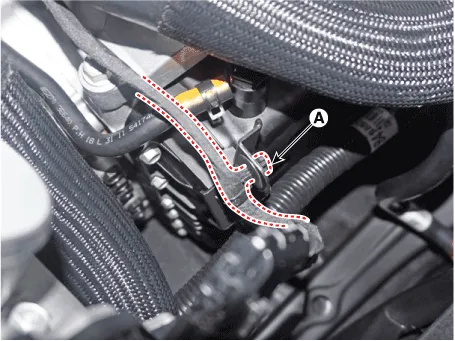

Remove the ground line (A).

|

| 8. |

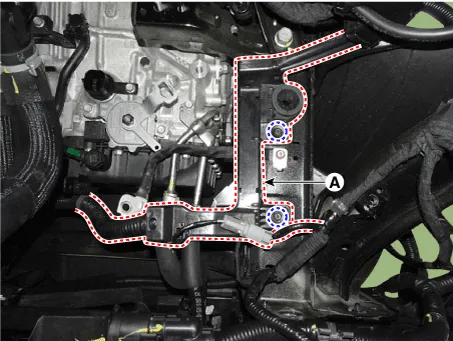

Loosen the bolts and then separate the engine wiring (A).

|

| 9. |

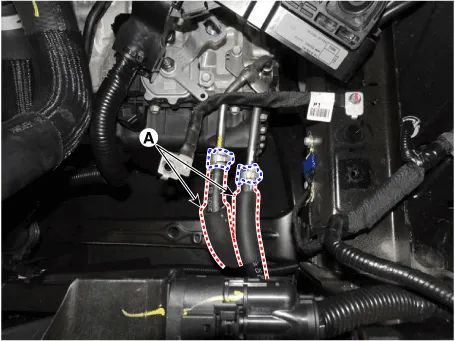

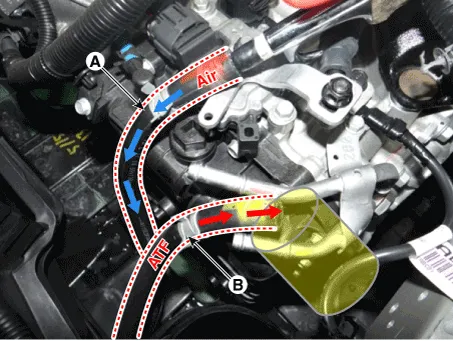

Separate the ATF cooler hose (A).

|

| 10. |

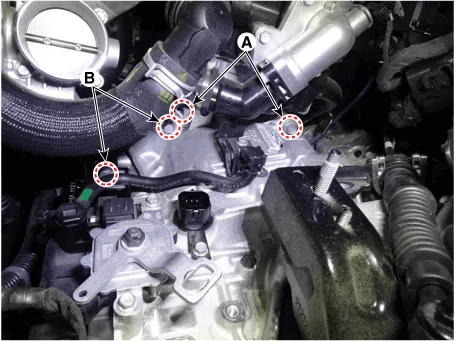

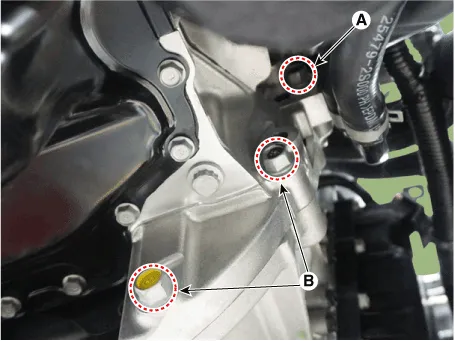

Loosen the transaxle upper mounting bolts (A) and the starter mounting

bolts (B).

|

| 11. |

Assemble the engine support fixture use a service special tools .(Beam

SST No.: 09200 - 3N000 Adapter SST No.: 09200-2W000, Engine fixture

adapter (rear) SST No.: 09200-L1100, Engine fixture adapter (front)

SST No.: 09200-L1200)

|

| 12. |

Using the engine support fixture (A), hold the engine and transaxle

assembly safely.

|

| 13. |

Remove the front wheel guard. [LH]

(Refer to Body (Interior and Exterior) - "Front Wheel Guard")

|

| 14. |

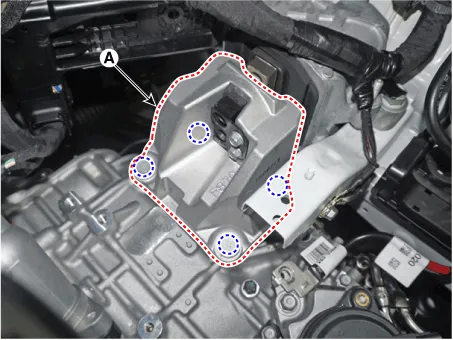

Loosen the transaxle bracket support mounting bolts (A).

|

| 15. |

Loosen the bolts and then removing the transaxle bracket (A).

|

| 16. |

Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 17. |

Remove the sub frame.

(Refer to Suspension System - "Sub Frame")

|

| 18. |

Remove the driveshaft assembly.

(Refer to Driveshaft and Axle - "Front Driveshaft")

|

| 19. |

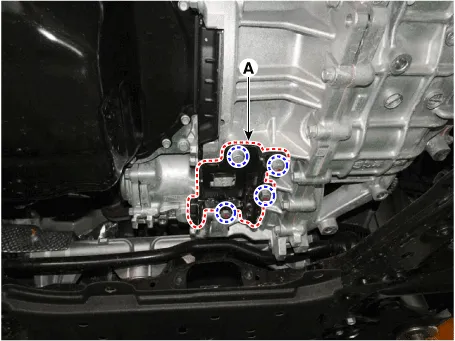

Loosen the bolts and then removing the roll rod support bracket (A).

|

| 20. |

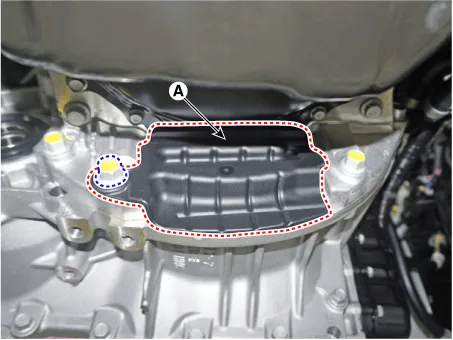

Remove the dust cover (A).

|

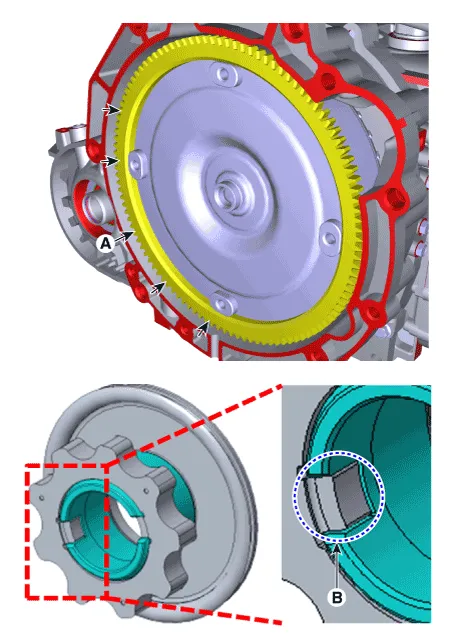

| 21. |

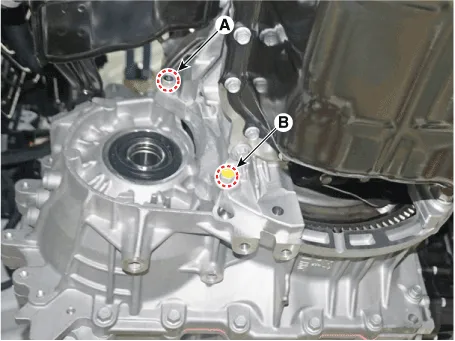

Loosen the mounting bolts (A) of the torque converter with rotating

the crankshaft.

|

| 22. |

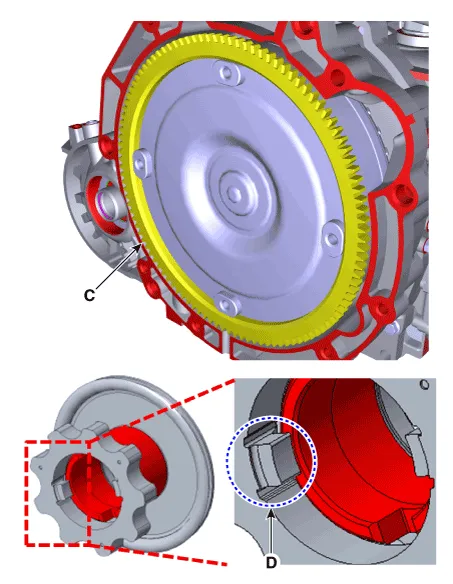

Remove the automatic transaxle with a jack after loonsening the mounting

bolts (A, B).

|

| Installation |

| 1. |

To install, reverse the removal procedure.

|

| 2. |

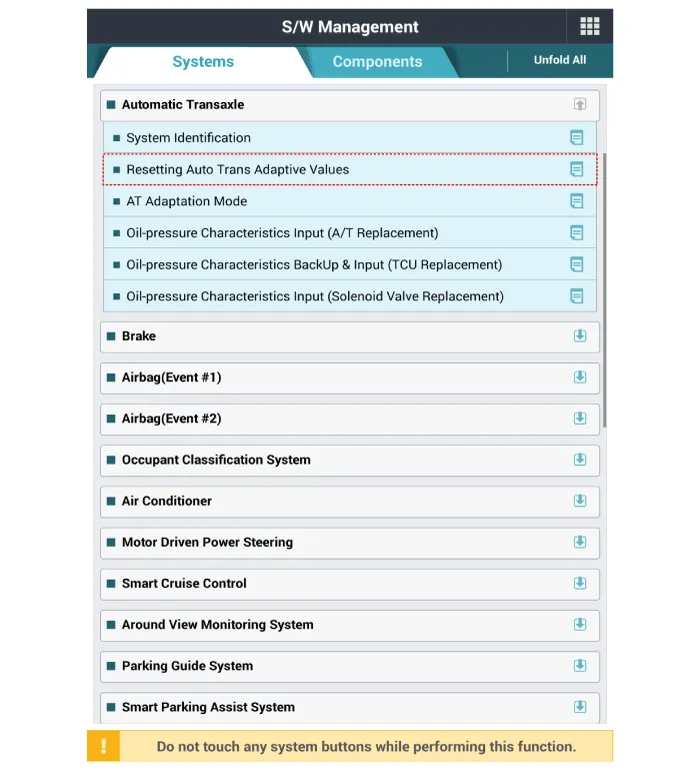

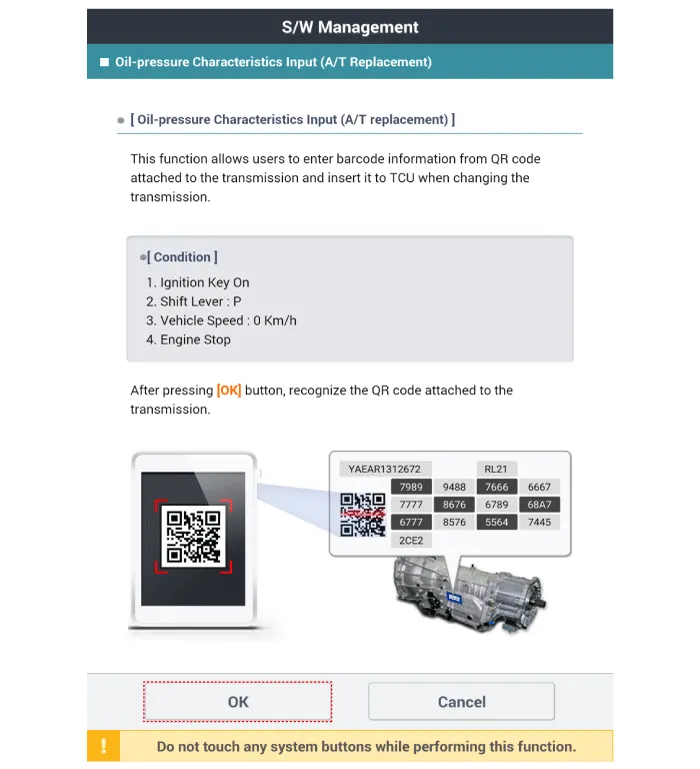

In case of the reinstallation.

|

| 3. |

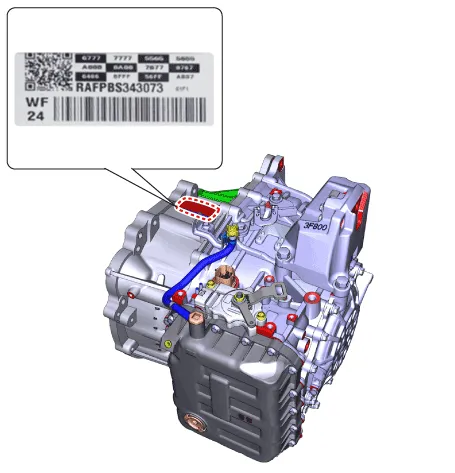

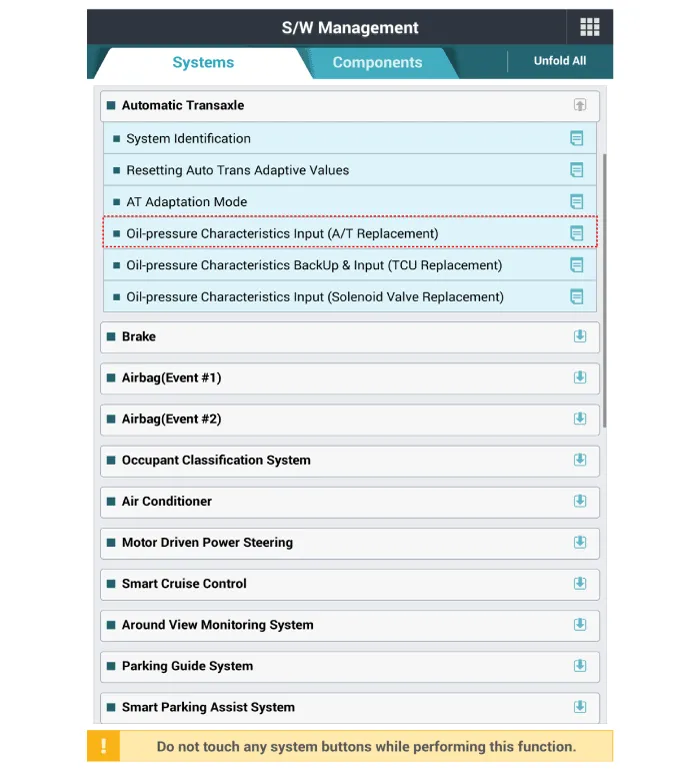

In case of the replacing with a new automatic transaxle.

|

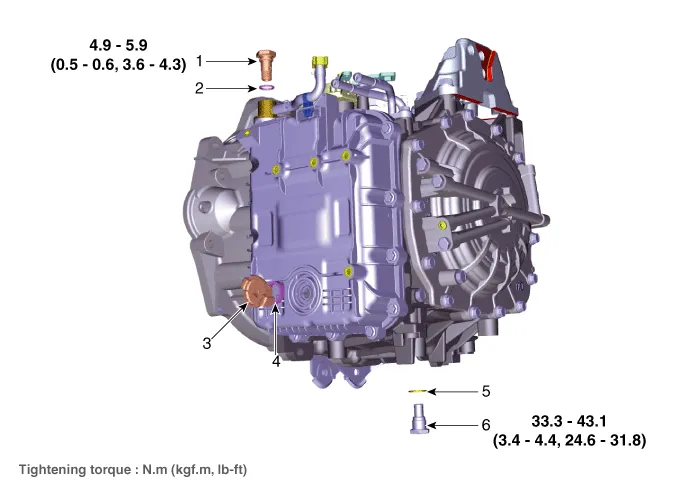

Automatic Transaxle Fluid (ATF). Components and components location

| Components Location |

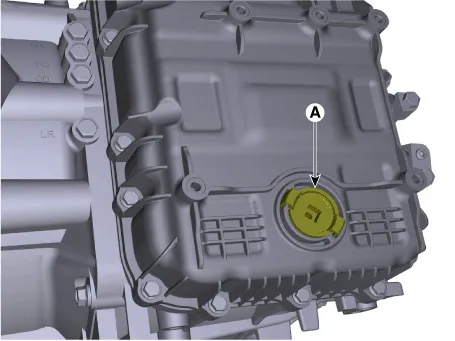

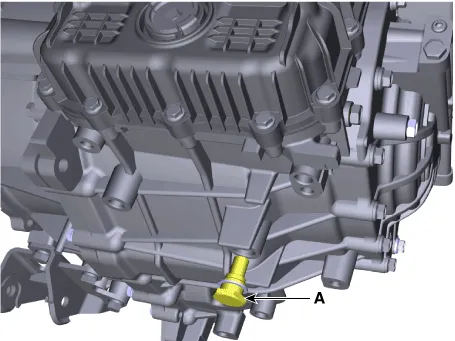

| 1. ATF Injection

plug (Eyebolt) 2. ATF injection plug gasket 3. ATF level check plug |

4. ATF level

check plug gasket 5. Drain plug gasket 6. Drain plug |

Automatic Transaxle Fluid (ATF). Repair procedures

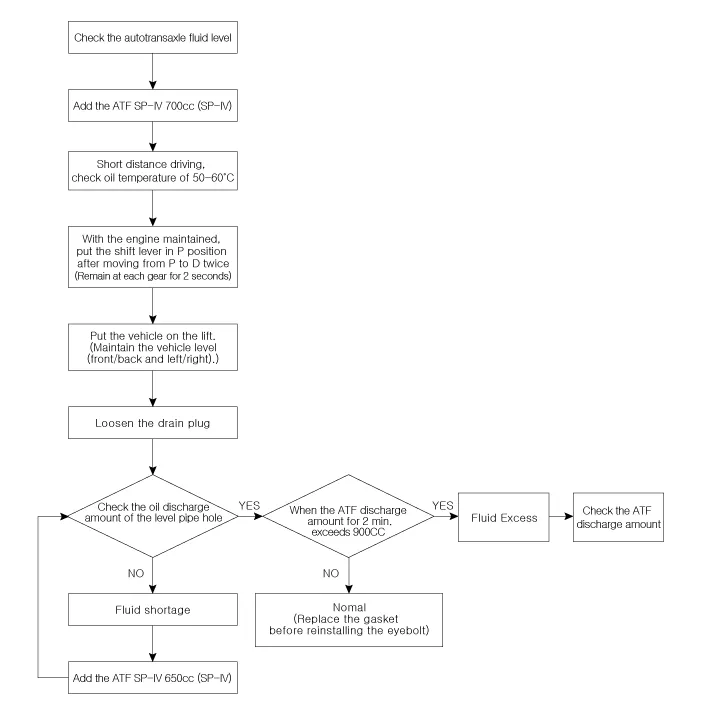

| Automatic Transaxle Fluid (ATF) Level Check |

|

| 1. |

Remove the air duct and air cleaner.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 2. |

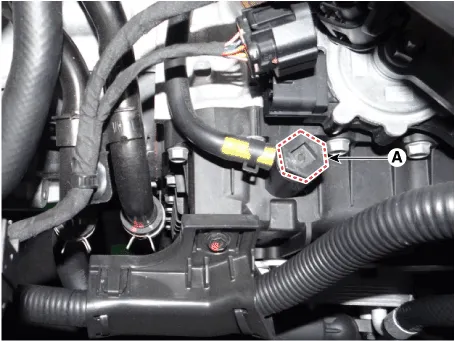

Remove the eyebolt (A).

|

| 3. |

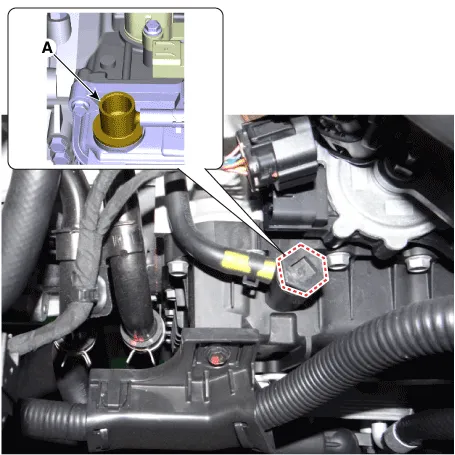

Add ATF SP-IV 700cc to the ATF injection hole (A).

|

| 4. |

Start the engine.

(Don’t step on brake and accelerator simultaneously.)

|

| 5. |

Confirm that the temperature of the automatic transaxle oil temperature

sensor is 50 - 60°C (122 - 140°F) with the diagnostic tool.

|

| 6. |

Shift the select lever slowly from “P” to “D”, then “D” to “P” and repeat

one more at idle.

|

| 7. |

Raise the vehicle, and make sure it is securely supported.

|

| 8. |

Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

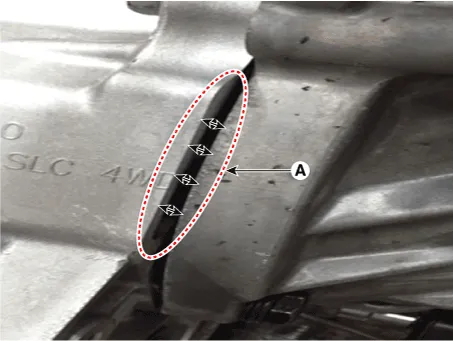

| 9. |

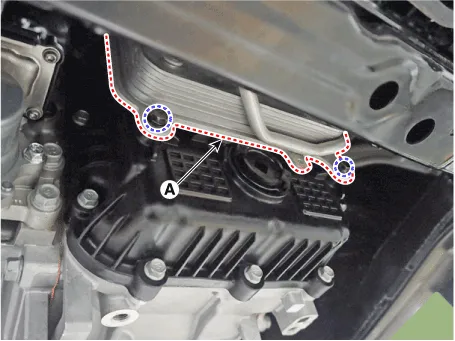

In case by ATF warmer, loosening the mounting bolts and then separate

the ATF warmer (A).

|

| 10. |

Remove the ATF level check plug (A) from the valve body cover.

|

| 11. |

If the ATF flows out of the overflow plug in thin steady stream, the

ATF level is correct.

Then finish the procedure and tighten the ATF level check plug.

|

| 12. |

Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 13. |

Put down the vehicle with the lift and then tighten the eyebolt (A).

|

| Replacement |

ATF of 8 speed automatic transaxle doesn’t be replaced. But, if the

vehicle is severe use or business use, replace ATF every 60,000 miles

for severe usage.

Severe usage is defined as

|

|

| 1. |

Remove the air duct and air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 2. |

Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 3. |

Remove the drain plug (A) and reinstall the drain plug after draining

ATF totally.

|

| 4. |

Put down the vehicle with the lift and then remove the eyebolt (A).

|

| 5. |

Add ATF SP-IV 700cc to the ATF injection hole (A).

|

| 6. |

Check the ATF level.

(Refer to Automatic Transaxle System - "Automatic Transaxle Fluid (ATF)")

|

| 7. |

Then finish check the ATF level procedure and install the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 8. |

Put down the vehicle with the lift and then tighten the eyebolt (A).

|

Special Service Tools Tool (Number and Name) Illustration Use 09200-3N000 Engine support fixture (Beam) Removal and installation of the transaxle.

Other information:

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Power Tailgate Module

Description and operation Description Power tailgate is an electro-mechanical system designed to provide power opening and closing of the tailgate through the push of a button of a remote key (fob), console switch, inner switch or an outside handle switch of the tailgate.

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Immobilizer System

Description and operation Description The immobilizer system will disable the vehicle unless the proper ignition key is used, in addition to the currently available anti-theft systems such as car alarms, the immobilizer system aims to drastically reduce the rate of auto theft.

Categories

- Manuals Home

- Hyundai Santa Fe Owners Manual

- Hyundai Santa Fe Service Manual

- Battery. Specifications

- Rear seats

- Maintenance

- New on site

- Most important about car