Hyundai Santa Fe (TM): Charging System / Alternator. Repair procedures

| Removal |

|

| 1. |

Turn the ignition switch OFF and disconnect the battery (-) terminal.

|

| 2. |

Remove the drive belt.

(Refer to Engine Mechanical System - "Drive Belt")

|

| 3. |

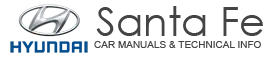

Disconnect the alternator connector (A).

|

| 4. |

Remove the cable nut (A) from the alternator "B" terminal.

|

| 5. |

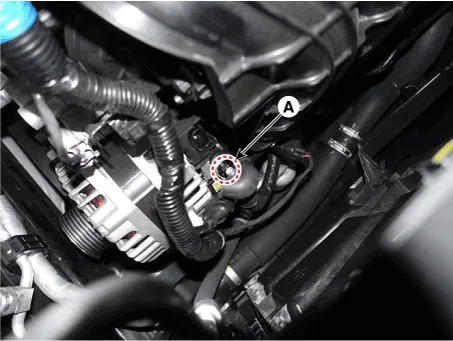

Remove the alternator mounting bolts.

|

| 6. |

Remove the alternator (A).

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

| Disassembly |

| 1. |

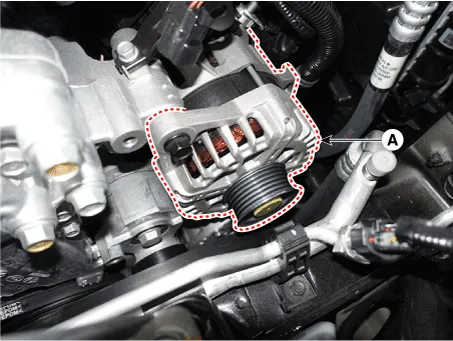

Remove the shaft cap (A).

|

| 2. |

Remove the OAP pulley (A).

|

| 3. |

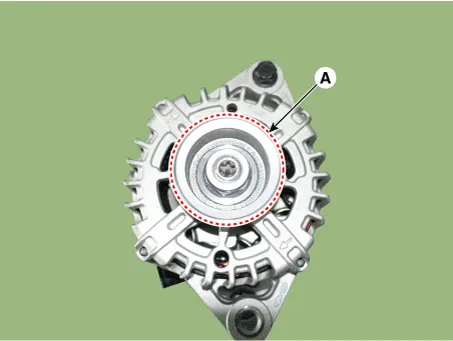

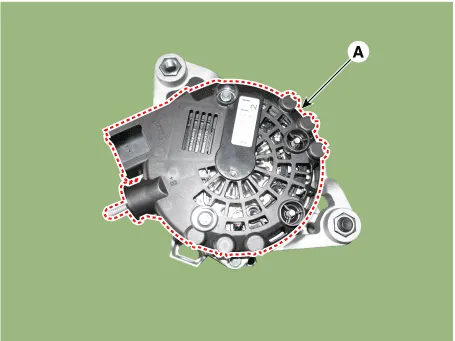

Remove the alternator cover (A) after loosening the mounting nut.

|

| 4. |

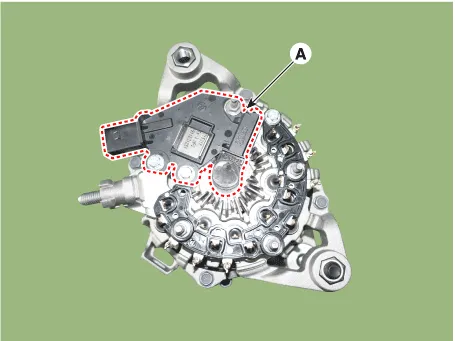

Remove the regulator assembly (A).

|

| 5. |

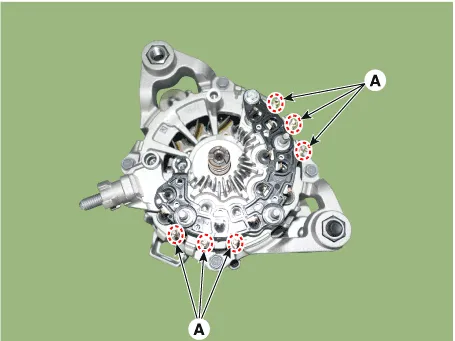

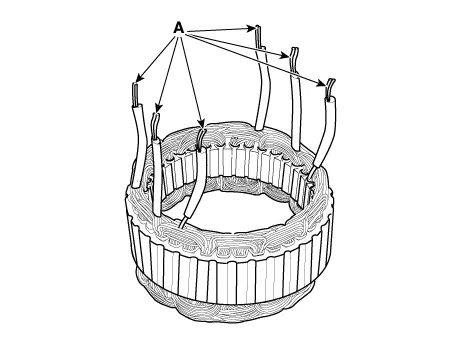

Remove the stator leads (A).

|

| 6. |

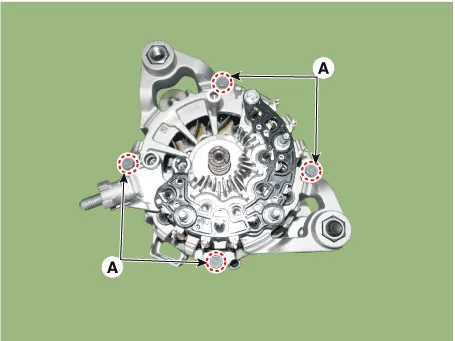

Remove the 4 through bolts (A).

|

| 7. |

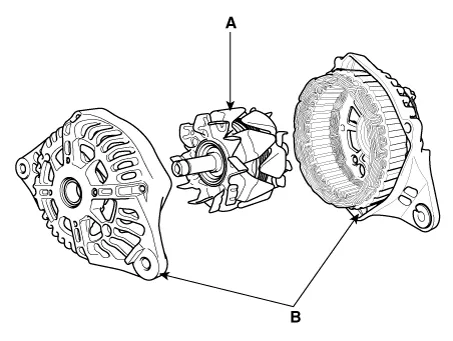

Separate the rotor (A) and cover (B).

|

| Reassembly |

| 1. |

Reassemble in the reverse order of disassembly.

|

| Inspection |

| 1. |

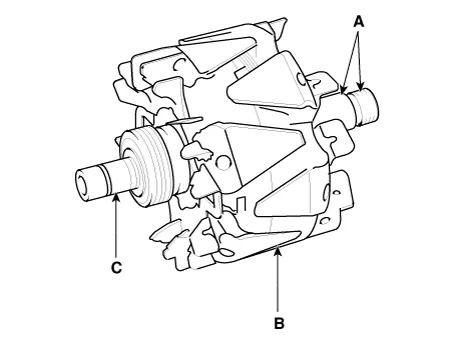

Check that there is continuity between the slip rings (C).

|

| 2. |

Check that there is no continuity between the slip rings and the rotor

(B) or rotor shaft (A).

|

| 3. |

If the rotor fails either continuity check, replace the alternator.

|

| 1. |

Check that there is continuity between each pair of leads (A).

|

| 2. |

Check that there is no continuity between each lead and the coil core.

|

| 3. |

If the coil fails either continuity check, replace the alternator.

|

Specification Item Specification Rated voltage 13.5V , 130A Speed in use 1,000 - 18,000rpm Pin 1 (LIN) Pulley Type OAP pulley

Description AGM Battery AGM battery is used for especially heavy load on the vehicle network depending on equipment and requirements.

Other information:

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Windshield Wiper/Washer

Components and components location Component Location 1. Windshield wiper arm & blade 2. Wiper & washer switch 3. Windshield washer hose 4. Windshield wiper motor & linkage 5. Washer motor 6.

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Parking Distance Warning (PDW)

Description and operation Description • PDW consists of 8 sensors (front : 4 units, rear : 4 units) that are used to detect obstacles and transmit the result in three separate warning levels, the first, second and third to IBU via LIN communication.

Categories

- Manuals Home

- Hyundai Santa Fe Owners Manual

- Hyundai Santa Fe Service Manual

- Battery. Specifications

- 4 Wheel Drive (4WD) System

- Restraint

- New on site

- Most important about car