Hyundai Santa Fe (TM): Air conditioning System / Compressor. Repair procedures

| Removal |

| 1. |

If a compressor is available, the air conditioner is operated for a

few minutes in the engine idle state and then the engine is stopped.

|

| 2. |

Disconnect the negative (-) battery terminal.

|

| 3. |

Recover the refrigerant with a recovery/charging station.

|

| 4. |

Loosen the drive belt.

(Refer to Engine Mechanical System - "Drive Belt")

|

| 5. |

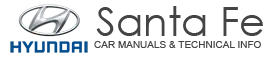

Loosen the mounting nuts and separate the suction line (A), discharge

line (B).

|

| 6. |

Press the lock pin and separate the ECV connector (A).

|

| 7. |

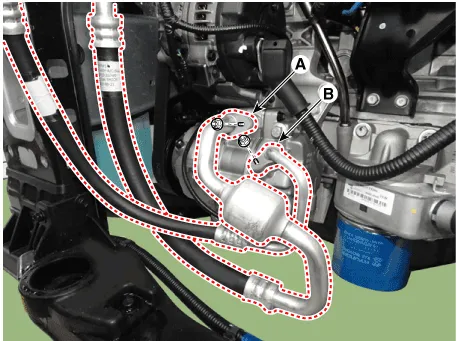

Loosen the mounting bolts and remove the compressor assembly (A).

|

| Installation |

| 1. |

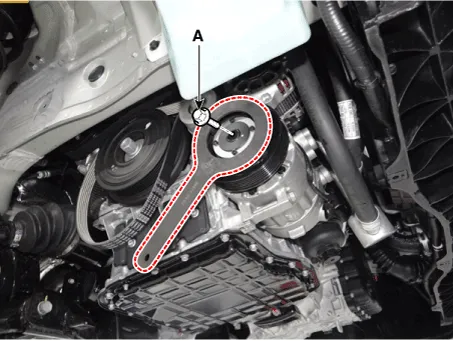

Make sure that the compressor (A) mounting bolt of the correct length

is screwed in. Tighten the mounting bolts in the specified tightening

order.

[Diesel 2.2 TCI-R]

[Execpt Diesel 2.2 TCI-RI]

|

| 2. |

Install in the reverse order of removal.

|

| Inspection |

| 1. |

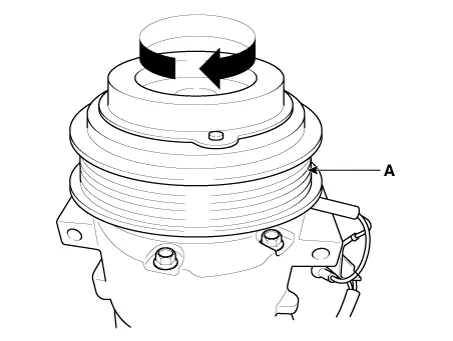

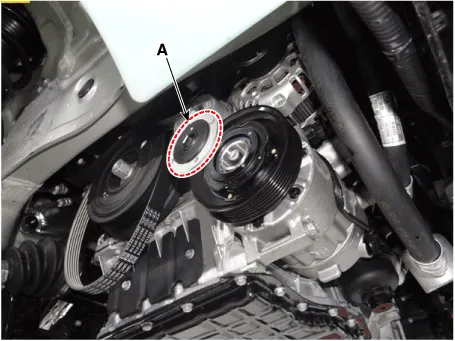

Check the pulley (A) bearing play and drag by rotating the pulley by

hand. Replace the pulley with a new one if it is noisy or has excessive

play/drag.

|

| External Control Valve Compressor Inspection (GDS) |

| 1. |

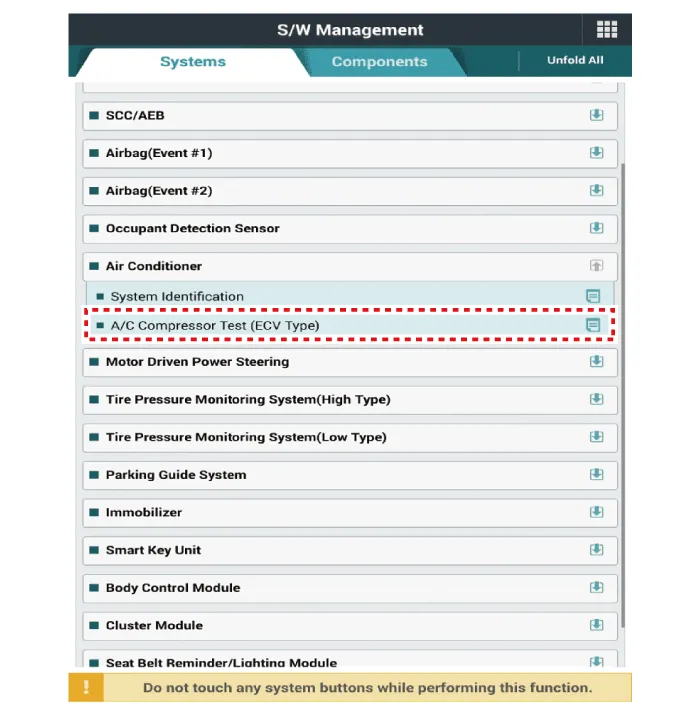

Connect GDS to the vehicle and select 'Aircon Compressor Test(ECV type)'

[ECV1]

|

| 2. |

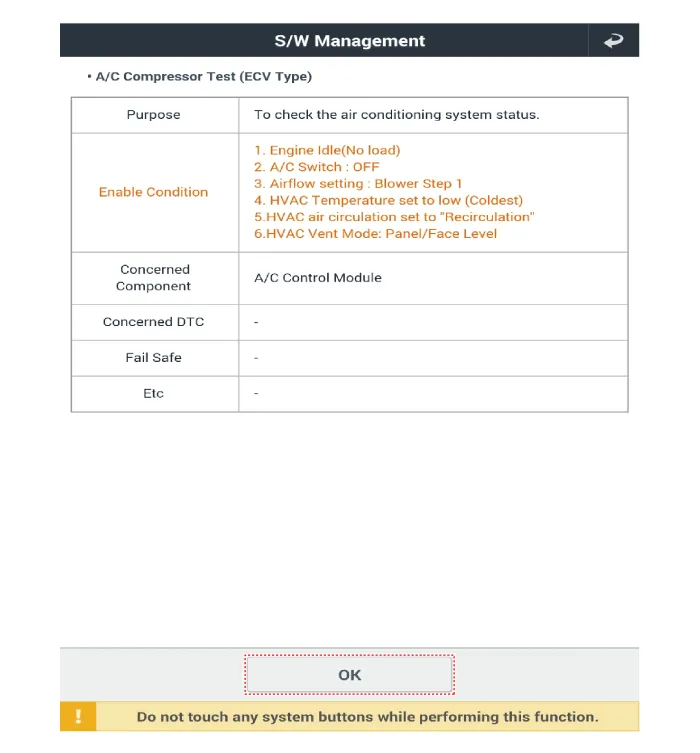

Make the vehicle ready as the GDS instruction on the monitor. (Turn

off A/C 'switch' only)

|

| 3. |

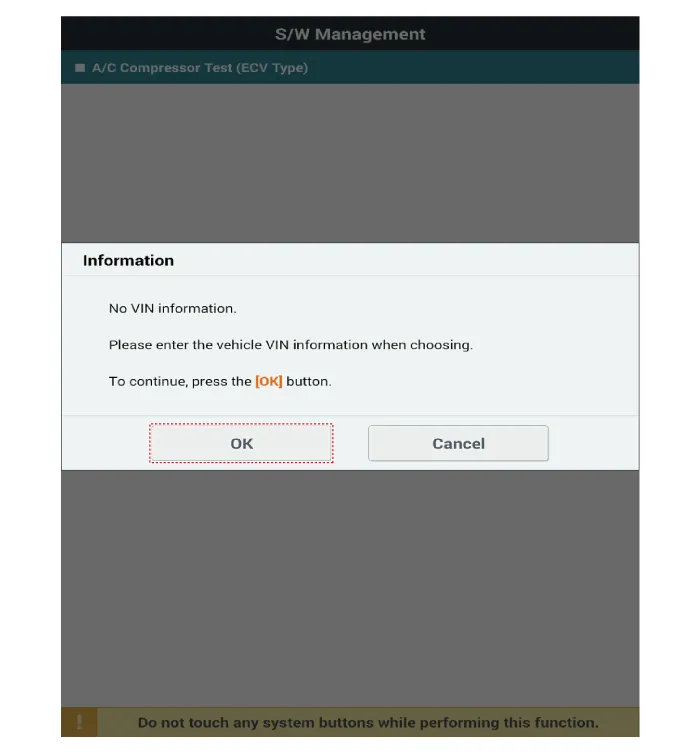

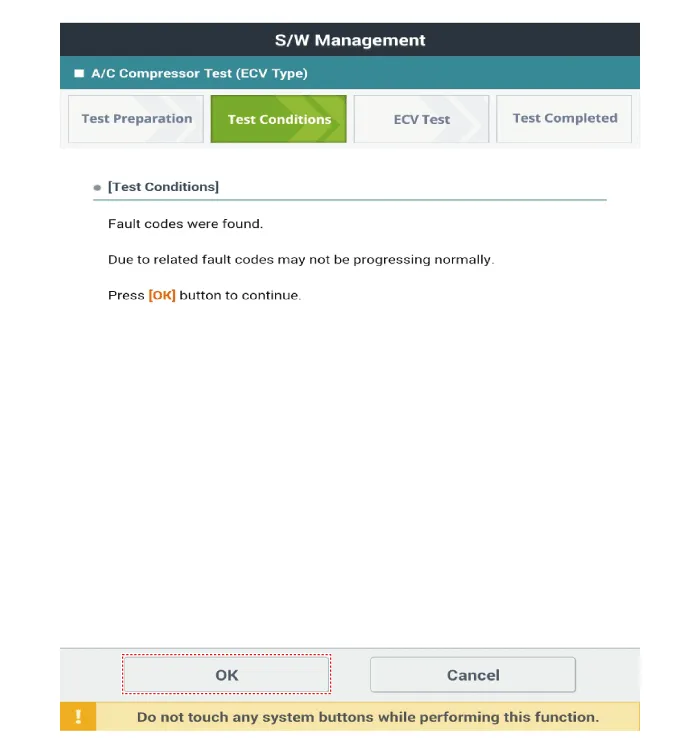

Check if other DTC codes are found before inspect ECV compressor. If

so, solve that problems first. If not, press 'OK' button to continue.

|

| 4. |

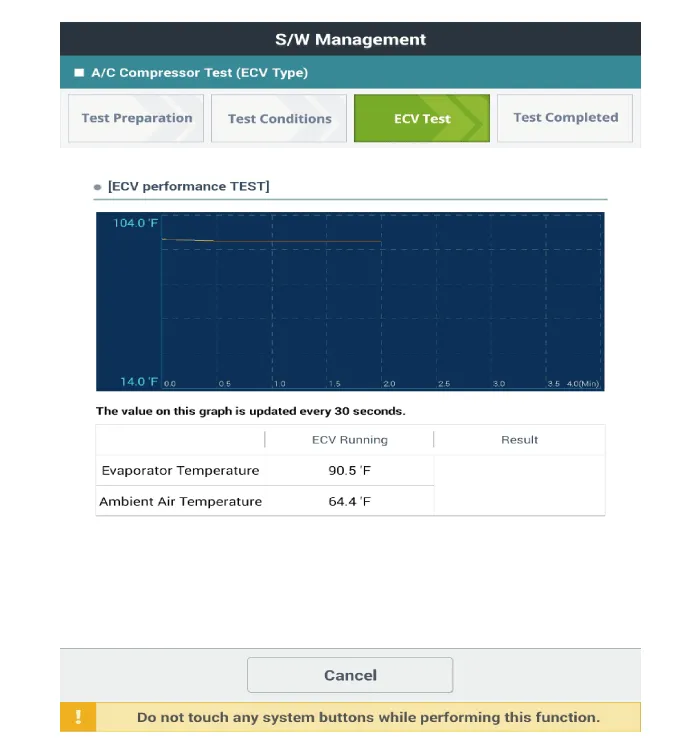

Start inspection

|

| 5. |

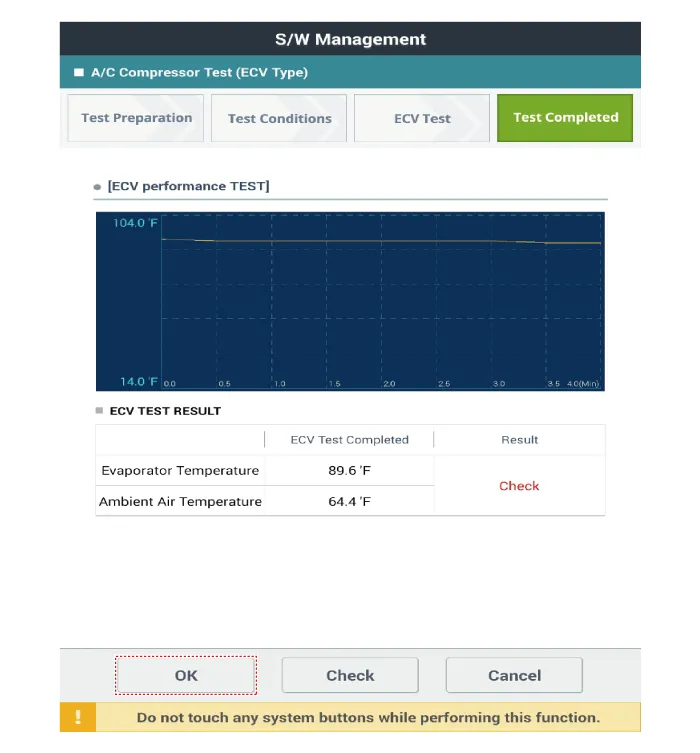

Check the result of inspection.

[ECV7]

[ECV8]

|

| 6. |

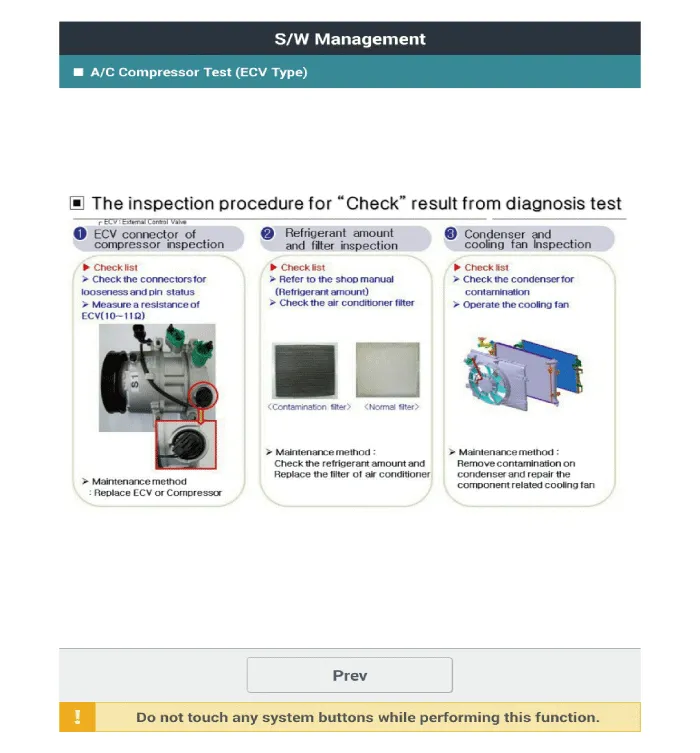

If the result shows "Check" , click "Check" and follow the instruction.

|

| 7. |

Inspect ECV again from the first step.

|

| Disassembly |

| 1. |

Remove the front tire [RH].

|

| 2. |

Loosen the drive belt.

(Refer to Engine Mechanical System - "Drive Belt")

|

| 3. |

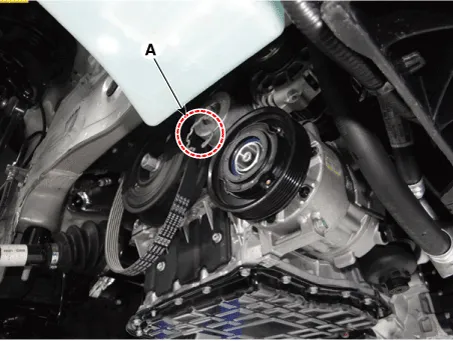

Remove the clutch bolt (A) while holding the pulley with a clutch bolt

remover (09977-3R000).

|

| 4. |

Loossen the limiter bolts and then remove the limiter & hub assembly.

|

| 5. |

Remove the pulley (B) after removing the snap ring (A) with a snap ring

plier.

|

| 6. |

Reassemble in the reverse order of disassembly.

|

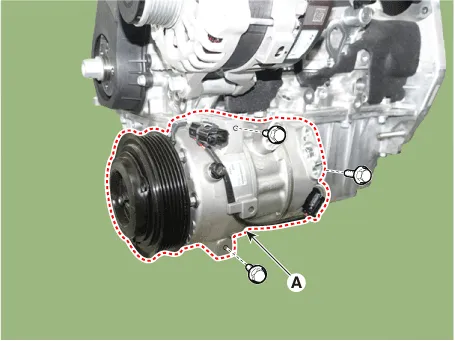

Components [Diesel 2.2 TCI-R] 1. Clutch Bolt 2. Disc & Hub Assembly 3. Clutch Spacer 4. Snap Ring 5. Pulley 6.

Components Location 1. Condensor

Other information:

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Wireless Power Charger System

Description and operating principle Description and Operation Wireless Power Charger System During ACC or IG ON, battery voltage is supplied to the wireless power charger system to transmit an output of 5 W to mobile phone. Mobile phones certified with the wireless charging standard WPC (Qi 1.

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Heater

Heater Unit. Components and components location Component Location 1. Heater Unit Assembly Components 1. Heater unit assembly 2. Heater NVH pad 3. Heater seal duct 4.

Categories

- Manuals Home

- Hyundai Santa Fe Owners Manual

- Hyundai Santa Fe Service Manual

- Vehicle Information, Consumer Information and Reporting Safety Defects

- Battery. Specifications

- Components and components location

- New on site

- Most important about car