Hyundai Santa Fe (TM): Automatic Transaxle System (SBC) / Automatic Transaxle Cooling System

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual / Automatic Transaxle System (SBC) / Automatic Transaxle Cooling System

Description and operation

| Description |

| • |

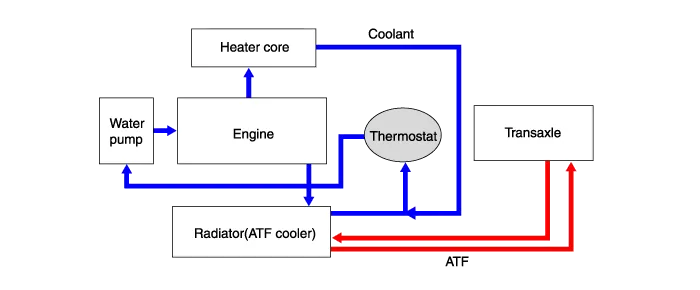

Engine coolant is used for circulating heat in order to heat and cool

the transaxle oil.

|

| • |

Prevents over heating of the transaxle oil while the vehicle is moving.

|

Coolant Flow

Oil Cooler. Repair procedures

| Repair procedures |

|

ATF Warmer. Description and operation

| Description |

The ATF warmer is mounted on the valve body cover to reduce oil viscosity friction

by increasing oil temperature under cold condition, which in turn improves fuel

efficiency. It is serial mounted on the entry of the Electronic Throttle Controller

(ETC), as shown in the diagram, and minimizes the effects of cabin heating system.

| • |

Engine coolant is used for circulating heat in order to heat and cool

the transaxle oil.

|

| • |

Rapidly elevates the transaxle oil temperature during the initial cold

start of the engine.

|

| • |

Prevents over heating of the transaxle oil while the vehicle is moving.

|

| • |

Transaxle oil warm-up and cooling can be done with a single system.

|

| • |

The water coolant and oil are separate in order to exchange heat.

|

ATF Warmer. Repair procedures

| Removal |

|

| 1. |

Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 2. |

Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 3. |

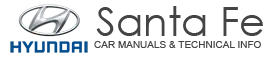

Loosen the drain plug (A) and then drain the coolant.

|

| 4. |

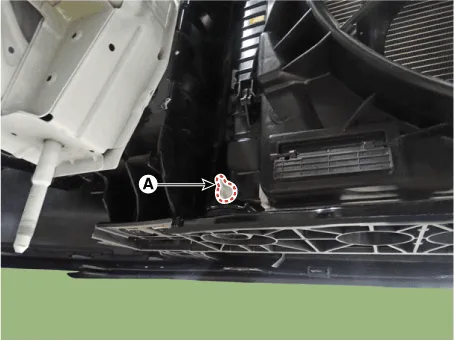

Separate the clamp and then removing the ATF cooler hose (A).

|

| 5. |

Loosen the ATF wamer upper mounting bolts (A).

|

| 6. |

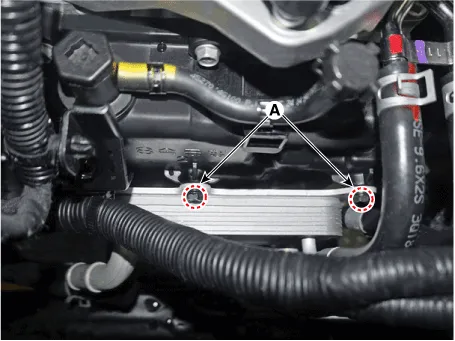

Separate the clamp and then removing the coolant hose (A).

|

| 7. |

Loosen the ATF wamer lower mounting bolts and then removing the ATF

warmer (A).

|

| Installation |

|

| 1. |

To install, reverse the removal procedure.

|

| 2. |

Check the ATF level after refilling the automatic transaxle with fluid.

(Refer to Automatic Transaxle System - "Automatic Transaxle Fluid")

|

| 3. |

Refil the coolant.

(Refer to Engine Mechanical System - "Coolant")

|

Inspection • Refer to the DTC manual for the check procedure.

Other information:

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: A/C Pressure Transducer. Repair procedures

Inspection • Before measuring the pressure of the refriferant line, check whether the refrigerant amount is charged in accordance with the specified charging amount.

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Description and operation

Categories

- Manuals Home

- Hyundai Santa Fe Owners Manual

- Hyundai Santa Fe Service Manual

- Instrument cluster

- Driving your vehicle

- Heating,Ventilation And Air Conditioning

- New on site

- Most important about car

Copyright © 2026 www.hsafe4.com - 0.0422