Hyundai Santa Fe (TM): Charging System / Alternator. Repair procedures

| Removal |

|

| 1. |

Turn the ignition switch OFF and disconnect the battery (-) terminal.

|

| 2. |

Remove the drive belt.

(Refer to Engine Mechanical System - "Drive Belt")

|

| 3. |

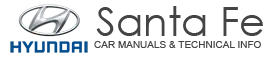

Disconnect the alternator connector (A).

|

| 4. |

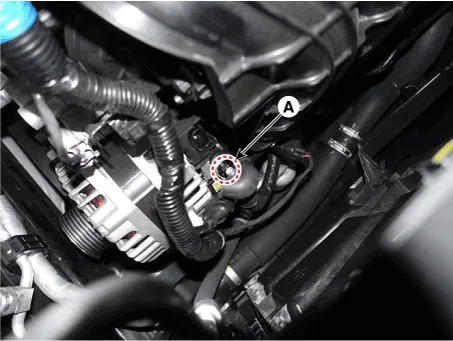

Remove the cable nut (A) from the alternator "B" terminal.

|

| 5. |

Remove the alternator mounting bolts.

|

| 6. |

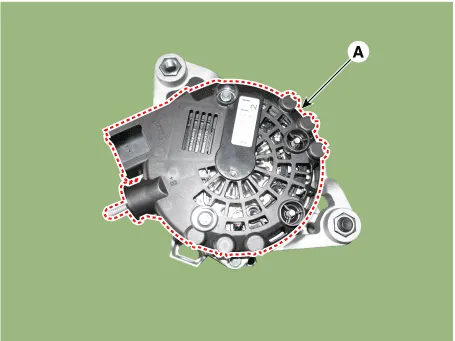

Remove the alternator (A).

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

| Disassembly |

| 1. |

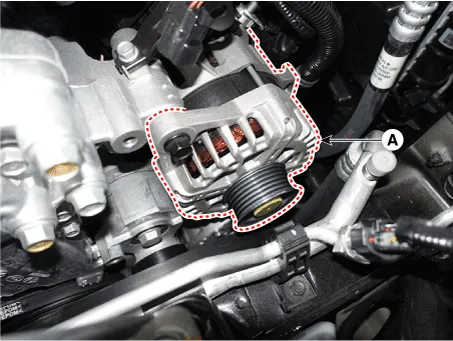

Remove the shaft cap (A).

|

| 2. |

Remove the OAP pulley (A).

|

| 3. |

Remove the alternator cover (A) after loosening the mounting nut.

|

| 4. |

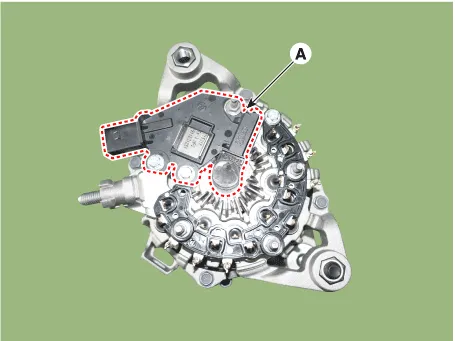

Remove the regulator assembly (A).

|

| 5. |

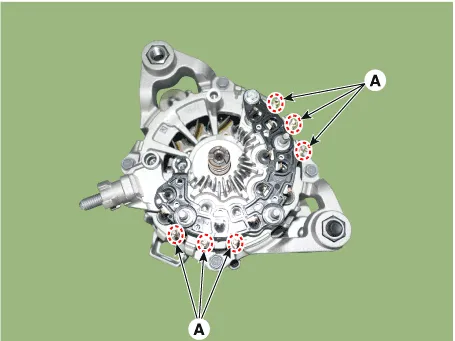

Remove the stator leads (A).

|

| 6. |

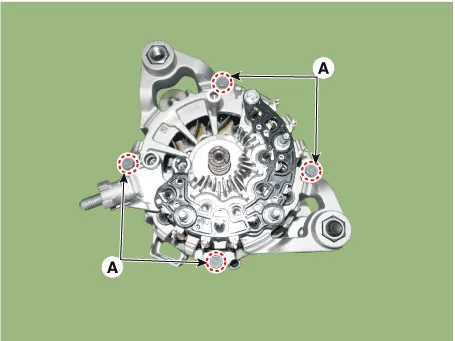

Remove the 4 through bolts (A).

|

| 7. |

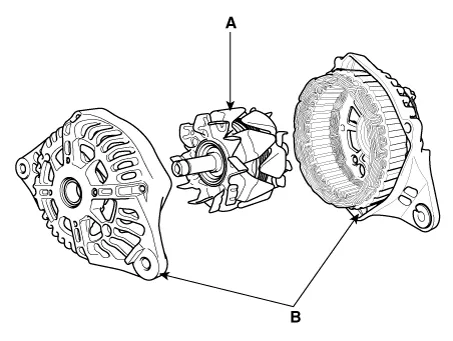

Separate the rotor (A) and cover (B).

|

| Reassembly |

| 1. |

Reassemble in the reverse order of disassembly.

|

| Inspection |

| 1. |

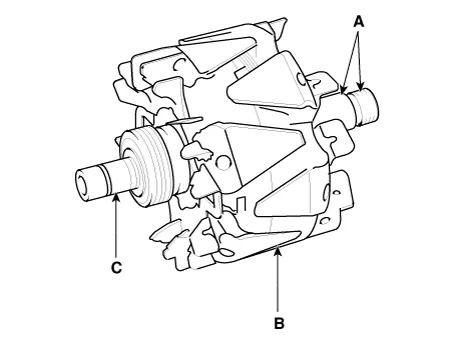

Check that there is continuity between the slip rings (C).

|

| 2. |

Check that there is no continuity between the slip rings and the rotor

(B) or rotor shaft (A).

|

| 3. |

If the rotor fails either continuity check, replace the alternator.

|

| 1. |

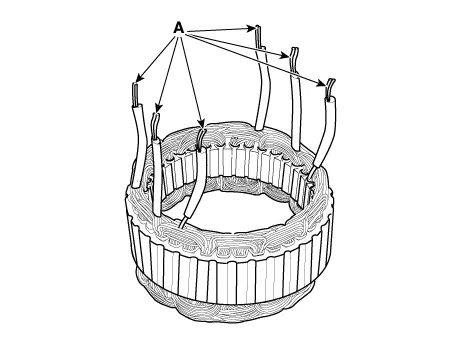

Check that there is continuity between each pair of leads (A).

|

| 2. |

Check that there is no continuity between each lead and the coil core.

|

| 3. |

If the coil fails either continuity check, replace the alternator.

|

Specification Item Specification Rated voltage 13.5V , 130A Speed in use 1,000 - 18,000rpm Pin 1 (LIN) Pulley Type OAP pulley

Description AGM Battery AGM battery is used for especially heavy load on the vehicle network depending on equipment and requirements.

Other information:

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Smart Key Diagnostic. Repair procedures

Inspection Self Diagnosis With Scan Tool It will be able to diagnose defects of SMART KEY system with diagnostic tool quickly. diagnostic tool can operates actuator forcefully, input/output value monitoring and self diagnosis.

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Rear Corner Radar System

Description and operation Description Rear Corner Radar is a system that measures the relative speed and distance from the following vehicles by using two electromagnetic wave radar sensors attached to the rear bumper, and detects any vehicle within the blind spot zone and gives off alarm.

Categories

- Manuals Home

- Hyundai Santa Fe Owners Manual

- Hyundai Santa Fe Service Manual

- Rear seats

- Front Radar Unit. Repair procedures

- Automatic Transaxle System (SBC)

- New on site

- Most important about car