Hyundai Santa Fe (TM): Hydraulic System / 35R Clutch Control Solenoid Valve (35R/C_VFS). Repair procedures

| Inspection |

|

| Removal |

|

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable.

|

| 2. |

Remove the air duct and the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 3. |

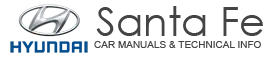

Separate the air bleed hose (B) and then wiring bracket (A)

|

| 4. |

Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

|

| 5. |

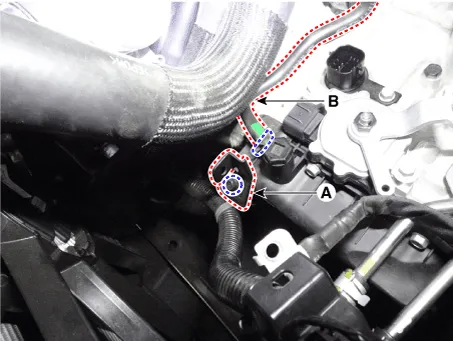

Remove the drain plug (A) and reinstall the drain plug after draining

ATF totally.

|

| 6. |

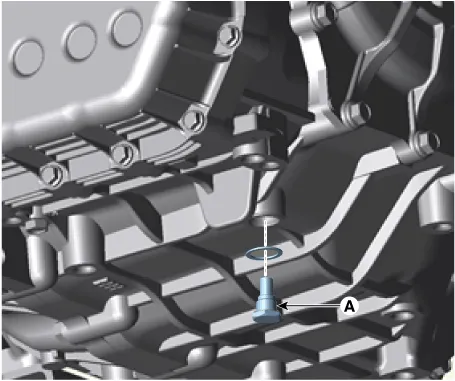

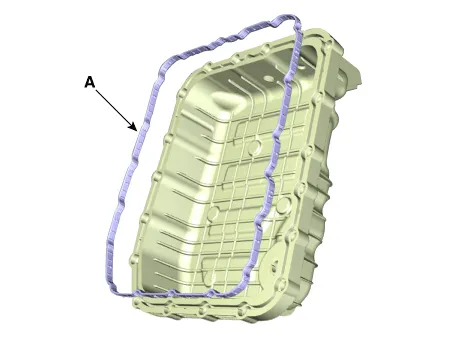

Loosen the mounting bolts (A) of the valve body cover.

|

| 7. |

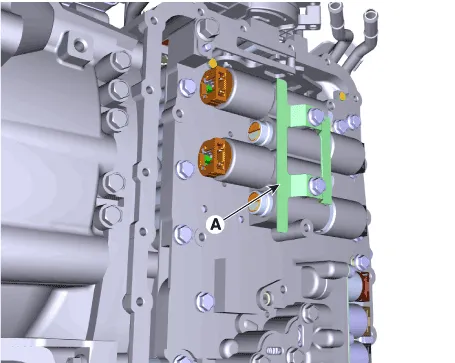

Loosen the bolts and then removing the main harness (A).

|

| 8. |

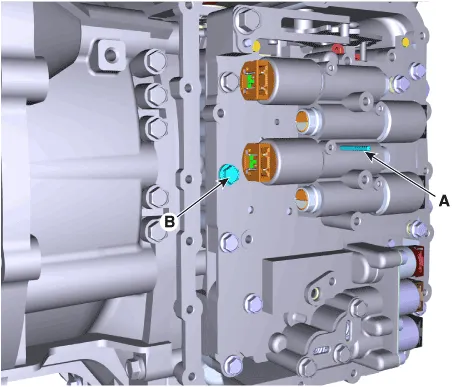

Remove the support bracket (A).

|

| 9. |

Remove the roller (A) and bolt (B).

|

| 10. |

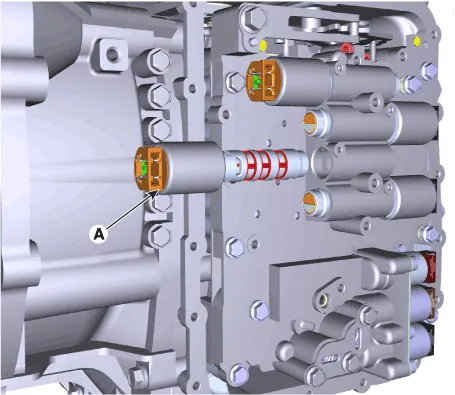

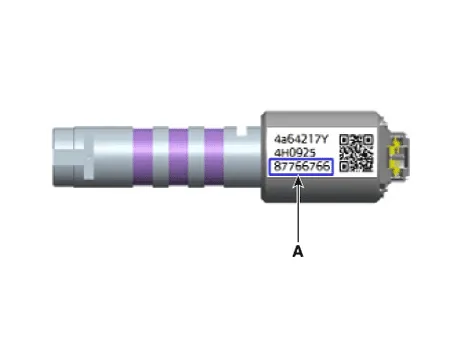

Remove the 35R clutch control solenoid valve (A).

|

| Installation |

|

| 1. |

To install, reverse the removal procedure.

|

| 2. |

Inject the automatic transaxle oil and inspect the oil level.

(Refer to Automatic Transaxle System - "Automatic Transaxle Fluid (ATF)")

|

| 3. |

Clear the diagnostic trouble codes (DTC) using the diagnostic tool.

|

| 4. |

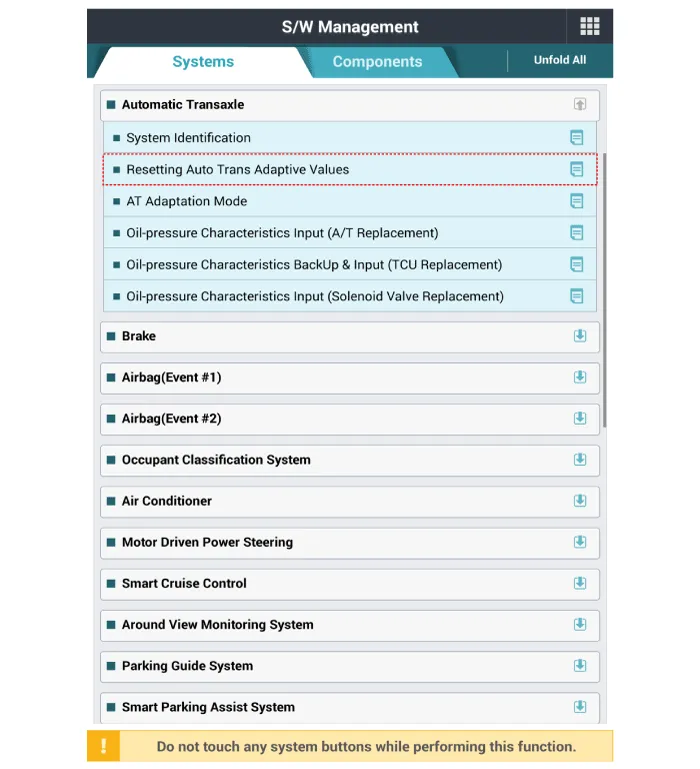

Reset the automatic transaxle adaptive values using the diagnostic tool.

|

| 5. |

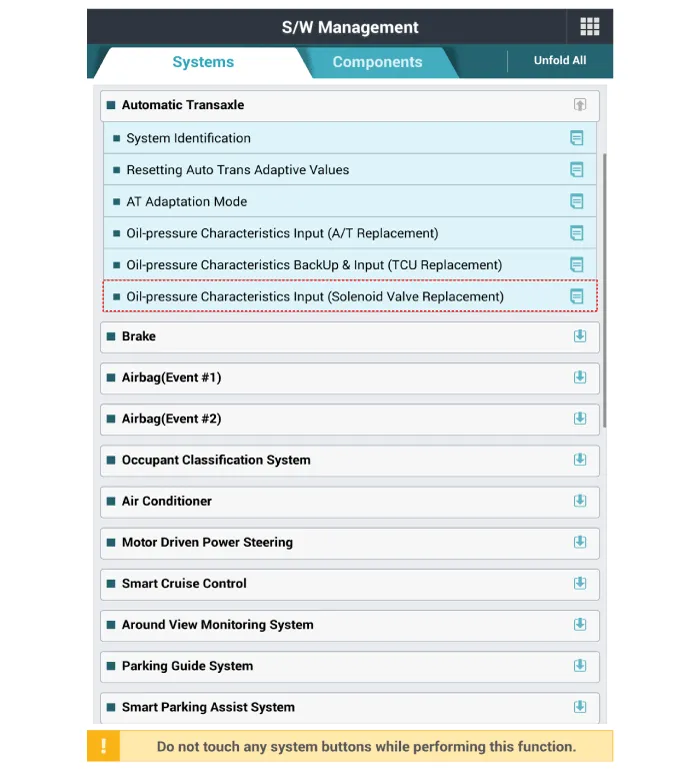

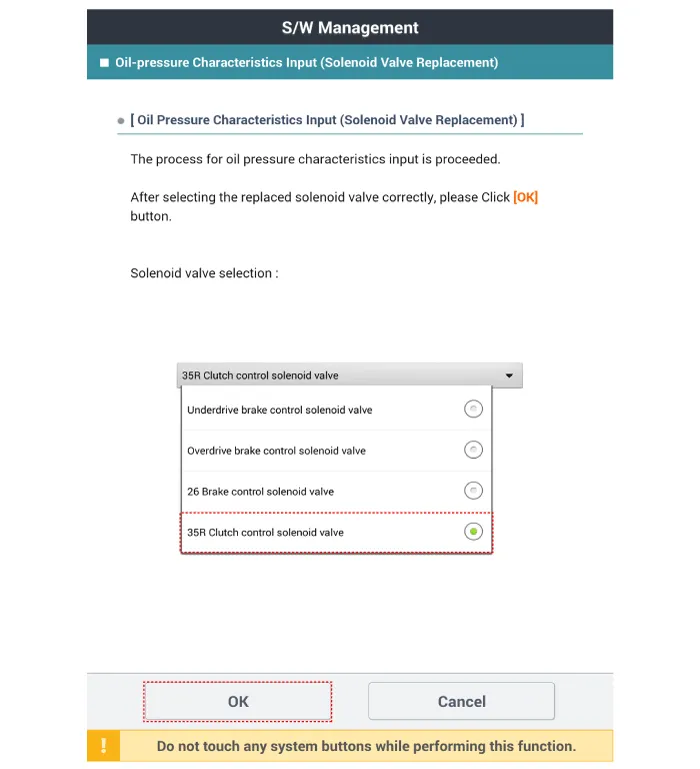

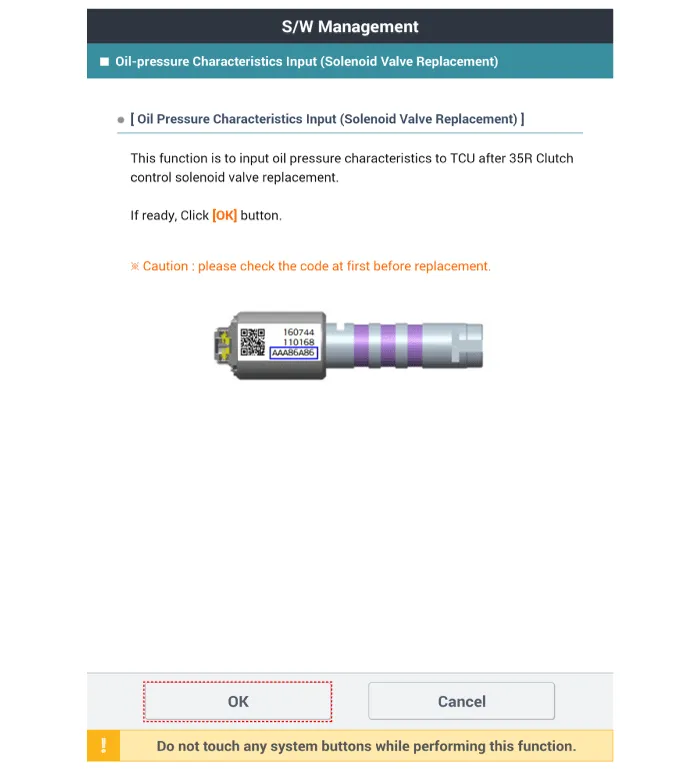

Input the oil pressure characteristics using the diagnostic tool.

|

| 6. |

In order to prevent start delay and gear shift shock during acceleration

and start, perform TCM learning after replacing the solenoid valve.

(Refer to Automatic Transaxle Control System - "Repair Procedures")

|

Specifications ▷ Control type : Normally low type Shape Items Specifications Control current [mA] 0 - 1100 Supply pressure [kpa (kgf/cm², psi)] 1569.

Description • Underdrive brake control solenoid valve(UD/B) is attached to the valve body. • This variable force solenoid valve directly controls the hydraulic pressure inside the underdrive brake.

Other information:

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Windshield Wiper/Washer

Components and components location Component Location 1. Windshield wiper arm & blade 2. Wiper & washer switch 3. Windshield washer hose 4. Windshield wiper motor & linkage 5. Washer motor 6.

Hyundai Santa Fe (TM) 2019-2023 Service and Repair Manual: Receiver-Drier. Repair procedures

Replacement 1. Using a Lwrench, remove the cap (A) on the bottom of the receiver-drier. 2. Remove the receiver-drier (A) from condenser using a long nose plier. Check for crumbled receiver-drier and clogged bottom cap filter.

Categories

- Manuals Home

- Hyundai Santa Fe Owners Manual

- Hyundai Santa Fe Service Manual

- Driving your vehicle

- Instrument cluster

- Vehicle Information, Consumer Information and Reporting Safety Defects

- New on site

- Most important about car